Capabilities

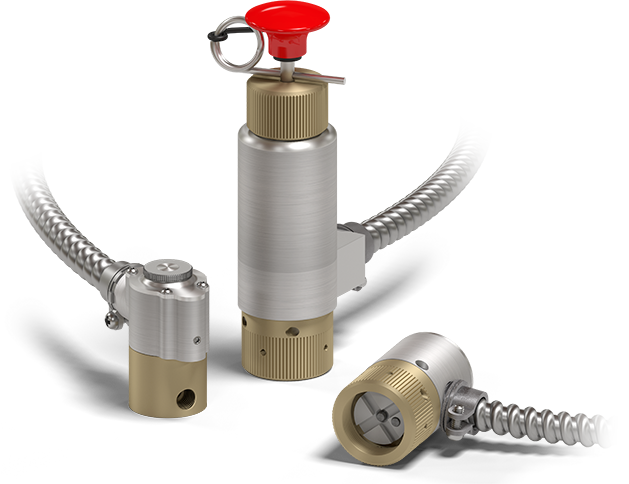

Custom Solenoid and Valve Design

TLX designs and develops custom electromagnetic actuators and valves. Our engineers begin by designing with 3D CAD and performing electromagnetic and fluid dynamic analysis with sophisticated, state-of-the-art finite element analysis software. Every design is engineered and tested in our lab to meet our customers’ specifications.

Applications Include:

- Thermal Management Controls

- High-Temperature Valves

- Proportional Solenoids

- High-Speed Dispensing Valves

- Pressure Release Valves

- Coolant Control Valves

- Emission System Controls

- Fire Suppression Actuators

- Natural Gas Control Valves

- Brake System Controls

- Climate System Controls

- High-Pressure Control Valves

- Transmission Control Valves

- Latching Solenoids

End-to-End Manufacturing

Lean and one-piece flow manufacturing are combined with in-process and end-of-line testing to produce consistently precise custom components. Lot codes and serial numbers are tracked so that each solution can be traced throughout the manufacturing and testing processes.

Lean Manufacturing

Lower volume production lines utilize lean manufacturing for quick changeovers. This allows TLX to build largely different products in the same area with maximum efficiency. Minimal setup time and reduced inventory yield savings that are passed downstream to our customers.

Cellular Manufacturing

Higher volume production lines at TLX use dedicated assembly cells based on lean principles. Value-stream mapping helps optimize process steps, providing the most competitive cost and quality proposition.

Comprehensive In-House Testing and Quality Assurance

Validation Testing

- Drop Test

- Humidity Cycling

- IP (Intrusion Protection)

- Salt Fog / Salt Spray

- Temperature Cycling

Solenoid Testing

- Coil Resistance

- Continuity

- Durability

- Force vs. Stroke

- Functional

- Hipot

- Mechanical Cycling

- Response

Valve Testing

- Flow Testing

- Flow Coefficient (Cv)

- Leakage

- Pressure

Outside Lab Testing

- Dust

- EMI

- Hardness

- X-Ray

“As of yesterday, we are using the new actuators in production and building with this improved component that addresses a significant warranty concern and provides a more satisfying ownership experience for our customers. TLX was a huge part of making this a reality.”

Current Customer

Your Reliable Partner from

Design to Delivery

Value-Added Services

TLX offers a variety of value-added services. With our extensive supply base and low-cost manufacturing, we can expand assembly to the next level of your assembly or system. Validation of the solenoid or valve in place at TLX can save time and streamline your workflow.

ISO-Certified Quality Management

TLX is an ISO accredited organization. Our processes are carefully monitored through statistical-based controls, helping to identify shifts in process spread and immediately take corrective action. Key performance indicators, advanced product quality planning, and 100% testing ensure the quality and performance of each and every component we build.

Consistent, On-Time Delivery

Communication is key to understanding your forecasted need with flexibility to adjust to unexpected fluctuations in requirements. Our processes are developed to match demand quantity to minimize finished goods and maximize response time. EDI, Kanban and long-term supply agreements are some of the tools used to ensure timely and accurate shipments.